Pics and Prose by Daniel Green

At present, the Perfect Group comprises three often intertwining divisions: Perfect Contracting – unrestricted demolition & hazmat removal; Perfect Hire – niche, specialised & long term labour hire; and Perfect Concrete Care – concrete cutting, coring, grinding, polishing, scanning and patching.

The Epicentre

Operating out of one centralised headquarters means clean and clear communication channels, efficient operational activity and shared lessons & assets. If Perfect Operations Managers Franky or Dave need a concrete care operator to swing by a job for some PCC magic then all they have to do is turn to Jaro sitting three feet away. Similarly if Tim needs a rail labourer for a week for John Holland then all he has to do is walk upstairs and ask.

Its Assign!

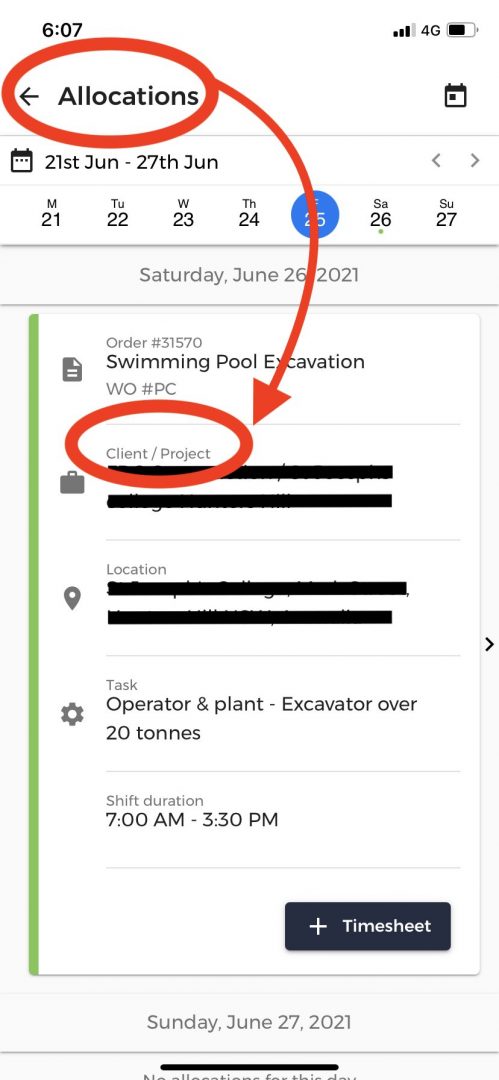

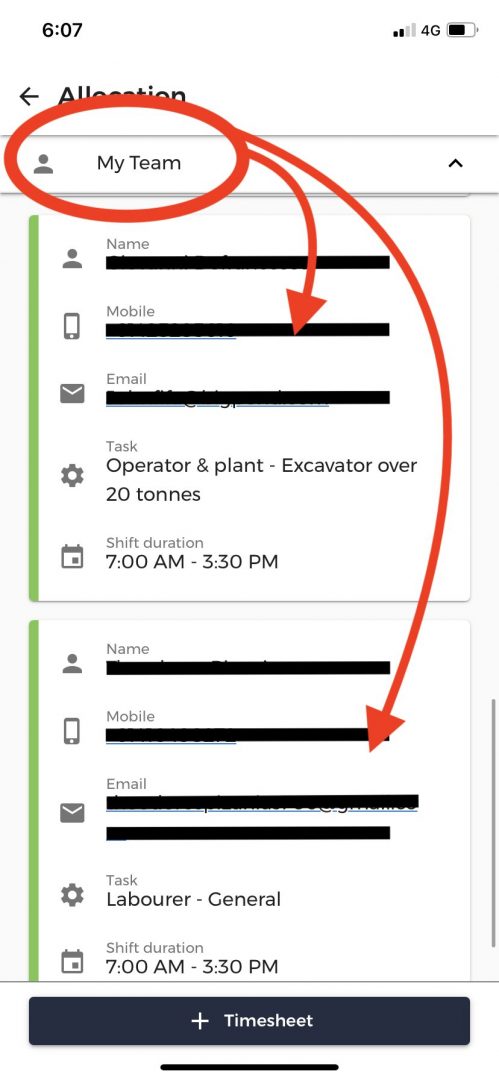

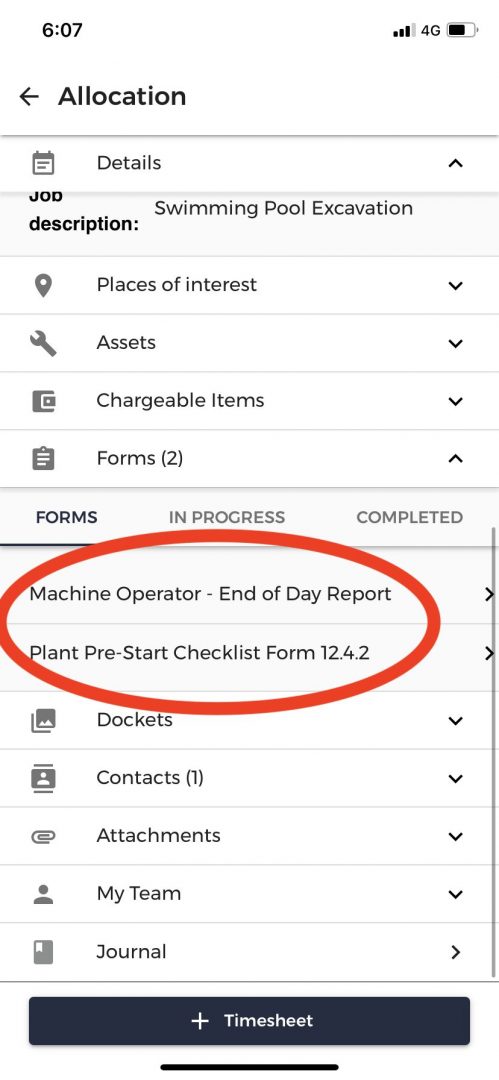

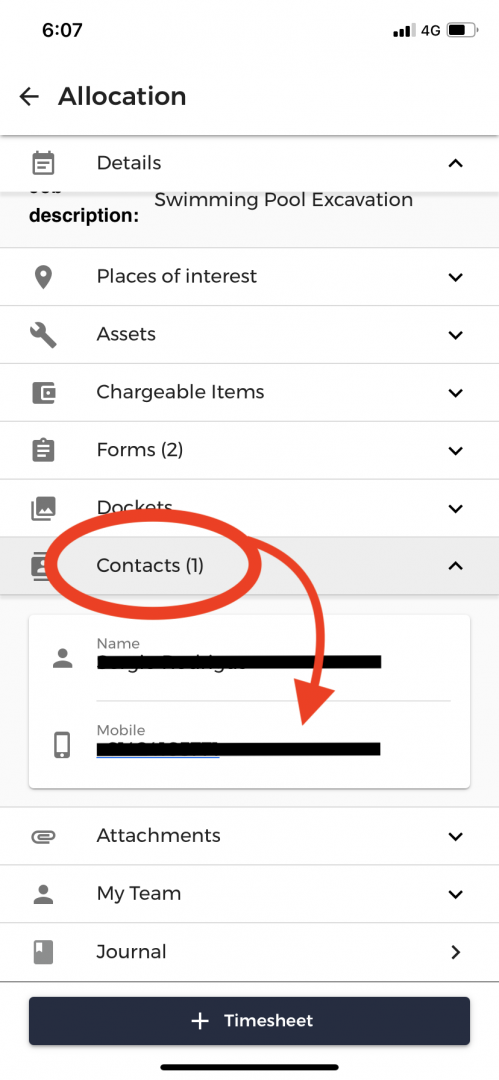

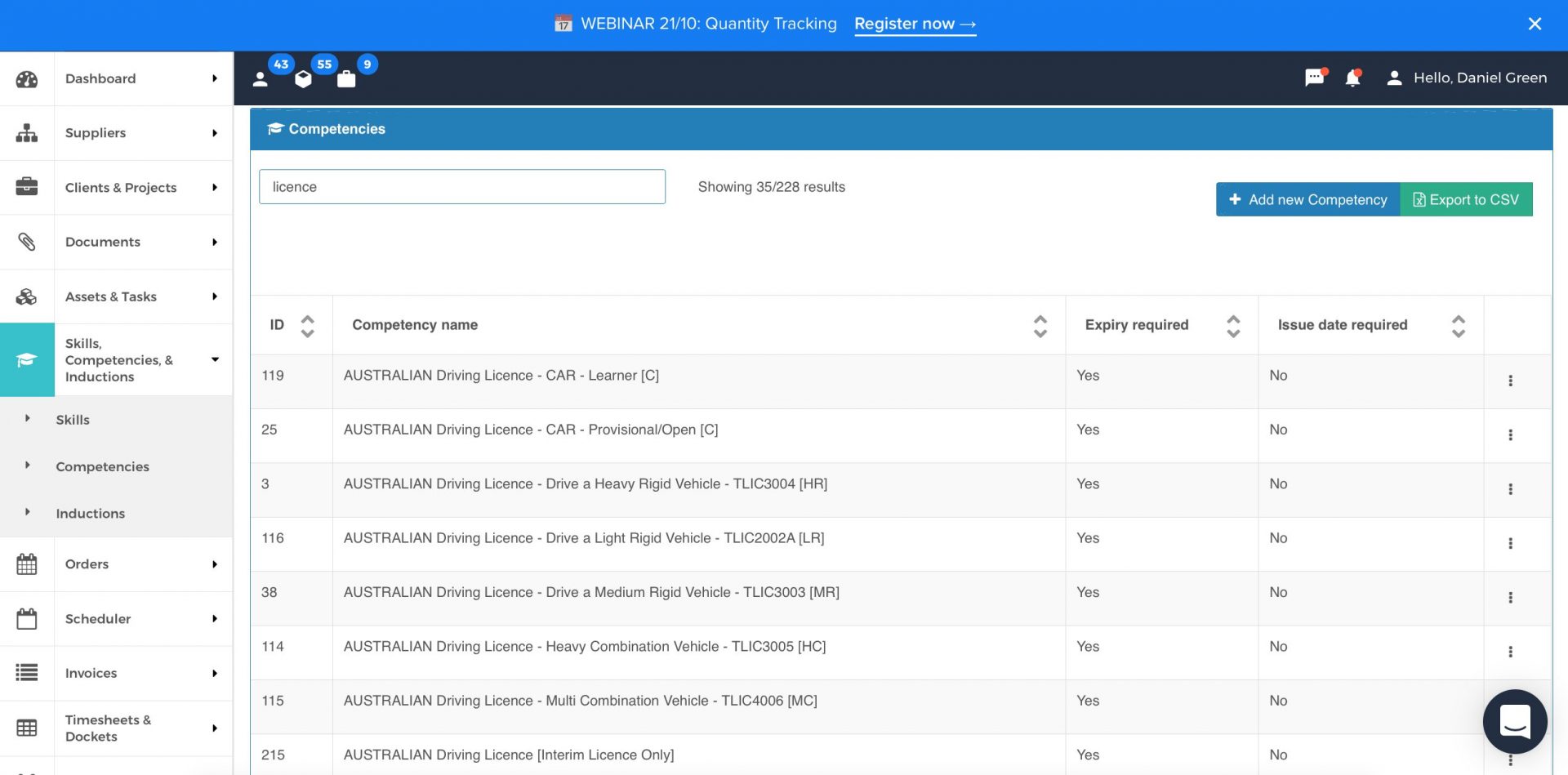

Perfect operates on a cloud based app called Assignar. In its simplest form its a workforce allocation and document completion program. In its most complex it records Perfect inductions, client inductions, tracks the service schedule of any machinery assets, worker leave, current and past orders, worker competencies, timesheets, communication via SMS, client projects, uniform issue, vehicle registration inspections and more.

Operación Eficiente

This means Perfect runs an extremely efficient operation. When a new worker is brought aboard, through Assignar they complete a 127 question induction, upload their tickets and qualifications and are issued Perfect rail shirts & PPE. They are trained how to use Assignar, allocated and sent on their way.

Let’s say this new worker misplaces their credentials on the way to site the next day. No white card no entry, right? Within moments one of Perfect HOD’s can have a hi-res copy of their tickets winging its way through time and space to the client. Problem solved in about four minutes.

What if the same worker is supposed to report to a Perfect supervisor upon their arrival. Ordinarily they’d call the office for the Sup’s name and number. But we streamlined that too. Instead of tying up Operations staff with a relatively low-ranking request, everything they need is in their allocation: the Sup’s name and number as well as the contact details of every other Perfect worker with the same allocation.

How about if they need to operate a Perfect machine that has been pre-delivered in a Perfect skip right to site? Except the client needs documentary proof of the inspection before they’ll let work begin. Perfect policy dictates that operators are required to pre-start machines prior to use. Guess where the pre-start form is? In the allocation. Once completed it is automatically sent to Perfect Operations for their records. The worker can also show the completed form to the client by accessing the completed forms menu in Assignar. If the client wants copy for their records then the worker can email the completed form to the client and it will arrive in their inbox in .PDF format.

And this is just in the Matrix.

Follow The White Rabbit

If you take the red pill and enter the real world, there’s tangible assets we use to increase productivity and safety.

Micro Moxies

Traditionally, tight access demolition jobs would require bucketing or barrowing spoil out to a truck or a skip. Whilst tried and true, this method is dated and can be hard on the body. With this in mind Perfect Founder/Director Matt Jedruszek invested in a fleet of electric dumpers. These Scandinavian wheeled tippers are revolutionising the way we operate. With a bin large enough to accomodate a 1.7t excavator mud bucket it can be loaded swiftly and driven out to a skip or a truck. The design allows for raising of the bin prior to tipping, meaning it can be lifted higher than the rail of the skip or truck and cleanly tipped inside. It will easily traverse tough terrain and hills, reducing the potentiality of sprained and rolled ankles by labourers carrying buckets. Finally, the energy expenditure of our workforce is significantly reduced. This translates to less errors, a more efficient operation and the maintenance of productivity throughout overtime – which traditionally drops off after a nine hour workday.

Remote Controlled

Similarly, Perfect Concrete Care mans a fleet of remote floor grinders. Used for a range of tasks like simple make goods through to entire floor remediation, the remote operational nature of the machine means less manual handling strain, less operator fatigue, a more precise finish and all the benefits that stem from these.

Peter Brokk

Another technological investment we’ve made is with demorobots in the form of Husky and Brokk machinery. These tracked demolition and load out are more akin to mechanised warfare than traditional demolition machinery and similarly have revolutionised the face of demolition. Powered by three- or five-phase mobile power cells they’ve eliminated the need for onboard internal combustion engines, thus extending their operational depth into more confined spaces. One such example is the tunnelling Perfect Contracting is undergoing in Mosman. As you scroll these pages, the operator is 26m underground at the end of a 31m stope manning a Brokk 200. At this particular job, the machine replaces the need for exhaustive overhead jackhammering, not just with brawn, but in the case of detailed demolition – with accuracy. Robots are simply far more exact than us flawed, weary humans.

Our Very Own T-800

Perfect continually invests in safer and efficient operational methods with the design and implementation of custom equipment – a flexibility we can maintain with the help of full time fabricator/electrician/operator/field-engineer Jarek Kotasinski. Recently, we needed to move 1200kg craneable bins of rubble up a lift shaft, across a disused pit, out into our work area and then up three stories of ramps to the Perfect skip located on the street. So with the approval of Perfect engineer Hisham Tarish, Jarek designed and manufactured the solution. The lifting was done via a gantry crane powered by a 12v Landcruiser winch. Then the bins were then pulled along an I-Beam rail system using a second winch – they were lowered to the slab. A third winch – mounted to the counterweight of one of our forklifts – pulled the bins up to street level where the fork tipped the rubble into the skip with its rotator attachment.

No Fate

Perfect is at the leading edge of operational flexibility in demolition and construction. We follow Japanese Kaizen theory, where decisions and planning are made at multiple levels for the overall aim of efficiency and safety, knowing full well that we will never achieve perfection in these two realms – but that we will try anyway.

We Get It Done, Safely [and Efficiently]

For more information on our services, take a look at our webpage or request a free quote.

contact us today